HBE Offers

Unmatched flexibility in the industry: >3.0°ppd at 23°C (73°F), with identical performance to FBE.

Excellent long-term performance: cathodic disbondment of less than 7 mm at 95°C, which is the best in its class.

Easy to apply formulation: the material's build and curing characteristics make it ideal for fast deployment installation.

HBE-95

Applied to bare steel, HBE-95 has proven to withstand operating temperatures up to 95°C (203°F) with superior performance. HBE-95 is used for protection of field joint girth welds, valves and fittings, as a holiday repair material on FBE coated pipe or for rehabilitation projects. This environmentally friendly, 100% solids, novolac epoxy system can either be spray applied or brush applied to the intended substrate.

Environmentally

Friendly

HIGH BUILD EPOXY COATING FOR PIPELINES

HBE-95

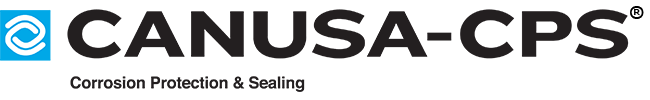

Applied to bare steel, HBE-95 has proven to withstand operating temperatures up to 95°C (203°F) with superior performance. HBE-95 is used for protection of field joint girth welds, valves and fittings, as a holiday repair material on FBE coated pipe or for rehabilitation projects. This environmentally friendly, 100% solids, novolac epoxy system can either be spray applied or brush applied to the intended substrate.

Corrosion Protection up to 95°C

HBE-95 coating system was designed to protect operating pipelines up to 95°C with exceptional performance.

Exceeds FBE Performance Requirements

Exceeds FBE coating performance requirements, including impact resistance, hot water soak adhesion and resistance to cathodic disbonding, as specified in USA (NACE RP0394), British (CW6), and Canadian (CSA Z245.20) standards.

Fast, Medium and Slow Cure Options

HBE-95 brush grade comes with three different cure speed options: Fast, Medium and Slow. Cure speed options present pot-life flexibility based on ambient temperatures and cycle time requirements.

High Build in Single Coat

A single pass application direct-to-metal will achieve a high build coating thickness of 20-40 mils (500-1000 microns).

Variety of Uses

Mainline pipelines, rehabilitation projects, girth weld field joints, damage and holiday repair to FBE coated pipe, pipeline valves, fittings and bends, or directional drilling applications.

Environmentally

Friendly

HIGH BUILD EPOXY COATING FOR HIGH FLEX APPLICATIONS

HBE-FLX

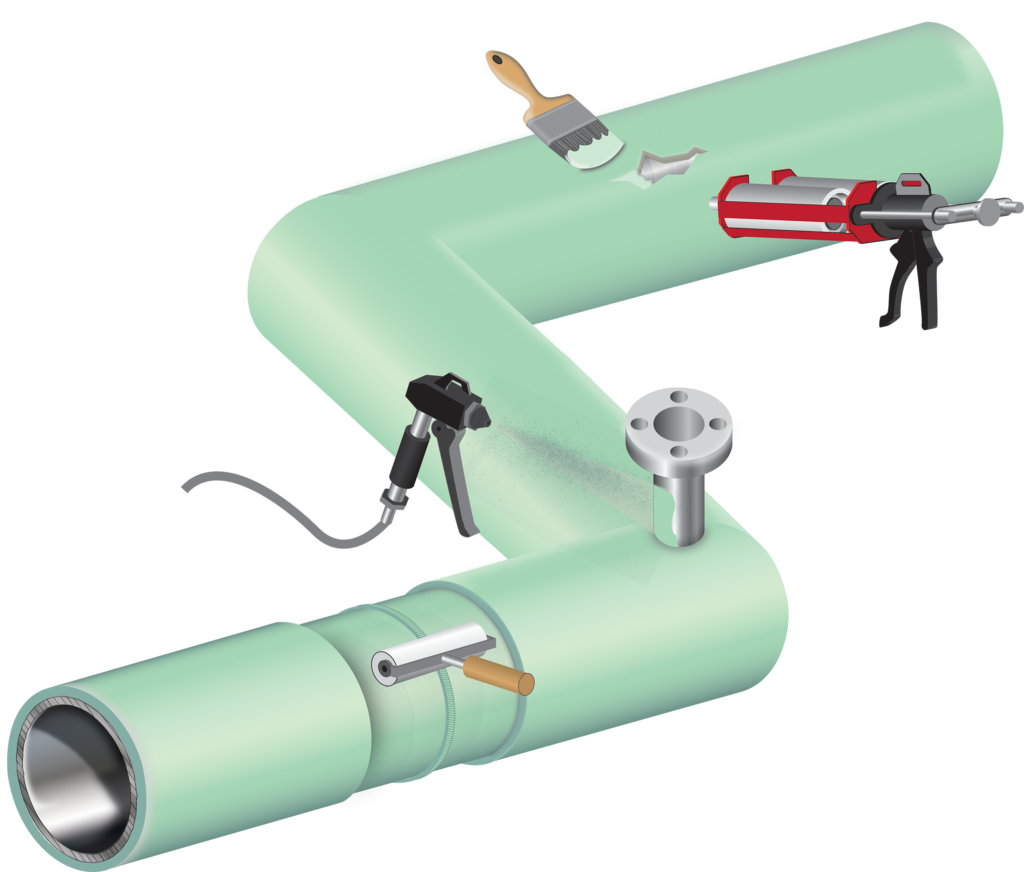

Matching flexibility criteria down to 0°C (32°F), HBE-FLX has been specifically formulated for high flex applications and is rated for pipeline operating temperatures up to 95°C (302°F). HBE-FLX is used for protection of linepipe, field joint girth welds, valves and fittings, as a holiday repair material or for rehabilitation projects. The coating is also well suited for directional drilling, thrust boring, rocky terrain, tank linings and other high flex applications. This environmentally friendly, 100% solids, epoxy system can either be spray applied or brush applied to the intended substrate.

HIGH BUILD EPOXY COATING FOR HIGH FLEX APPLICATIONS

HBE-FLX

Matching flexibility criteria down to 0°C (32°F), HBE-FLX has been specifically formulated for high flex applications and is rated for pipeline operating temperatures up to 95°C (302°F). HBE-FLX is used for protection of linepipe, field joint girth welds, valves and fittings, as a holiday repair material or for rehabilitation projects. The coating is also well suited for directional drilling, thrust boring, rocky terrain, tank linings and other high flex applications. This environmentally friendly, 100% solids, epoxy system can either be spray applied or brush applied to the intended substrate.

High Flexibility

HBE-FLX can attain flexibility properties of >3.0° ppd at 23°C (73°F) and >2.0° ppd at 0°C (32°F) without the use of urethane (isocyanate) chemistry.

Matches FBE Linepipe Requirements

HBE-FLX is compliant to CSA Z245.20-14 and ISO 21809-2:2014 test requirements from 95°C (302°F) down to 0°C (32°F).

Protection up to 95°C

HBE-FLX coating system was designed to protect operating pipelines up to 95°C (302°F).

Directional Drill Compatibility

High flexibility, tensile elongation, impact, gouge and abrasion resistance are all coating properties that are maximized for directional drilling suitability.

High Build in Single Coat

A single pass application direct-to-metal will achieve a high build coating thickness of 20-40 mils (500-1000 microns).

Contact Us

Would you like to know more about our HBE Products? Or to allow us to calculate the minimum bending radius for your project, please complete the form.